Renew Your Protective Industrial Coatings to Stop Corrosion

- By: Nova Construction Team

- Published:

- Updated: December 19, 2025

You may have heard the saying, “an ounce of prevention is worth a pound of cure.” This saying is especially relevant for fighting industrial corrosion in construction and manufacturing environments.

What can you do to prevent corrosion before it becomes a big issue?

The main solution is to regularly renew your protective industrial coatings with professional service and advanced coating repair technology. These coatings serve as a shield for important equipment, protecting them from weather, water, and other damaging elements.

Learning about how corrosion works, how coatings help, and why keeping them in good shape matters can help businesses extend equipment lifespan, reduce repair bills, and keep operations running smoothly.

It’s not just about slapping on a coating; you need a thoughtful, active approach with proper system design that helps your equipment last longer and work better.

What Is Corrosion and Why Is It a Problem for Industry?

Corrosion is the process where metals slowly break down because of things like water or chemicals reacting with the surface. This reaction, often seen as rust on iron or steel, happens when the metal meets oxygen or water.

Over time, corrosion eats away at the strength of metal parts, which can mean sudden equipment failure and big safety risks.

Factories, construction sites, and other industrial facilities use a lot of metal in their equipment and buildings, so corrosion can be a serious and expensive issue here. Left unchecked, it slowly destroys materials, leading to lost money, frequent repairs, and worries about worker safety.

Without a proper protective treatment system to keep out water, chemicals, or salt, metal parts and concrete structures will wear out even faster, sometimes becoming impossible to restore.

Main Causes of Industrial Corrosion

- Moisture: Water in the air can settle on metal surfaces and wall structures, starting rust and other corrosion — especially in damp or changing temperatures.

- Chemicals: Acids, salts, and industrial chemicals can quickly speed up the corrosion process when they touch metal surfaces. Construction workplaces like chemical plants or those near the ocean are at extra risk.

- Temperature Changes: Both hot and cold shifts can cause condensation or activate chemical reactions that lead to corrosion, affecting project performance.

- Pollution and Salt: Airborne pollutants and salt spray, especially near the sea, cause more rapid damage to equipment and wall surfaces.

- Bad Maintenance: Not cleaning or looking after equipment allows harmful materials to pile up, making corrosion worse and reducing overall system lifespan.

What Happens If You Ignore Corrosion?

If corrosion isn’t handled quickly with proper coating repair service, it can lead to higher repair bills, the need to replace parts or machines more often, and long periods when equipment can’t be used. This loss of use can cost a business money and slow down operations.

There are also safety risks. Damaged metal can lead to leaks or even structural collapse, especially in areas like oil refining, manufacturing, or construction work.

Delaying repairs raises the danger of serious accidents, pollution, or unexpected equipment breakdowns. Spotting corrosion early is important-making repairs sooner can save money and prevent disasters that could affect an entire project.

How Protective Industrial Coatings Prevent Corrosion

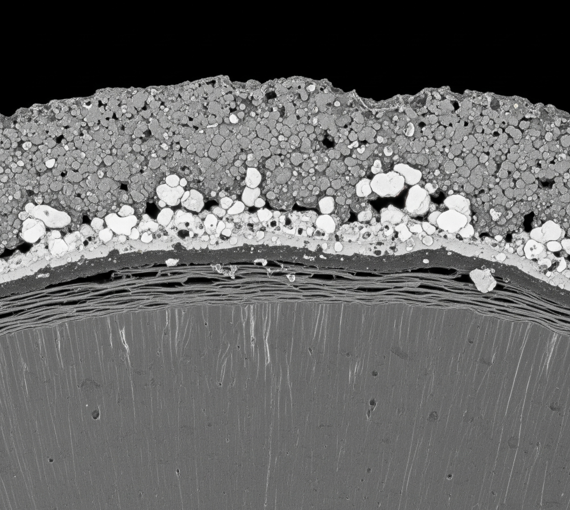

Protective coatings for industrial sites are like armor for your equipment. They form a tough layer that keeps out water, air, and other harmful materials using advanced technology.

Most coatings start as a liquid, paste, or spray that dries into a solid, tight film, stopping the chemical reactions that cause corrosion.

By forming a seal, these coating systems stop water and oxygen from reaching the metal. Some coatings also use chemicals to slow down corrosion or include metals that will corrode instead of the main piece.

Many modern solutions use more than one of these methods, providing stronger protection and helping keep equipment in good shape for longer.

How Coatings Work to Protect

- Physical Barrier: Coatings form a smooth shield that blocks out water, oxygen, and chemicals from reaching wall and surface areas.

- Inhibitive Action: Some technical formulations have additives that slow the chemical reactions which cause corrosion.

- Sacrificial Coating: Certain solutions include zinc or other metals that will react and break down first, protecting the main item underneath.

Why Regularly Applying and Renewing Coatings Pays Off

- Longer equipment lifespan, which means fewer repairs or replacements.

- Cost savings from reduced damage and avoiding major breakdowns.

- Improved safety by keeping equipment strong and reliable.

- A cleaner, better-looking finish on machinery, wall surfaces, or metalwork.

- Enhanced project performance and operational efficiency.

Types of Protective Industrial Coatings

There are several kinds of protective industrial coatings, each suited to different problems or environments. Choosing the right solution depends on where and how it will be used, and proper system design is crucial for optimal performance.

| Type | Main Features | Best Uses |

|---|---|---|

| Epoxy | Very strong, sticks well, resists chemicals | Pipelines, storage tanks, factories, marine settings |

| Polyurethane | Flexible, tough, resists sunlight and abrasion | Outdoor equipment, machinery, areas exposed to sunlight |

| Zinc-rich | Offers "sacrificial" rust protection using zinc | Steel bridges, marine structures, humid locations |

| Acrylic | Fast drying, keeps color, easy to use | General protection, places needing quick turnarounds |

| Specialty (Ceramic, Fluoropolymer, Intumescent, Alkyd) | Special needs like high heat, nonstick, or fireproofing | High temperatures, fireproofing, special environments |

How To Pick the Best Coating for Your Needs

- Material: Know what you are coating-steel, aluminum, concrete, etc. Some coatings are better for certain materials.

- Environment: Think about moisture, chemicals, temperature, and exposure to sunlight.

- Expected Wear: Decide if your equipment will face heavy use, lots of cleaning, or other tough conditions. Choose a coating that matches these challenges.

Get Advice from Certified Professionals

Because choosing and applying industrial coatings can be challenging, it’s a good idea to get technical service help from trained coating professionals. These experts can inspect your equipment, spot existing or potential problems, and recommend the best solution for your situation.

They can also provide guidance about the right application process and future inspection needs to keep your warranty intact and ensure proper system performance.

When Should You Renew Your Protective Industrial Coatings?

All coatings eventually wear out and need to be refreshed. Acting before they fail fully helps keep your equipment safe and avoids high repair bills that could impact your entire project.

Warning Signs It’s Time to Recoat

- Visible rust or changes in color

- Peeling, cracking, bubbling, or flaking of the coating

- Exposed metal or loss of gloss

- Crumbling parts or surface texture changes

Don’t just paint over rust — if you cover up corrosion, the problem will continue underneath. Heavily used or exposed areas, like those around water or chemicals, may need more frequent checks and coating repair service to maintain optimal lifespan.

What Happens If You Wait Too Long?

- Faster breakdown of equipment or building structures

- Higher repair costs and more downtime

- Greater chance of sudden failure or safety hazards

- Coating problems spreading to larger areas, making fixes more difficult and expensive

Fix small coating issues early to avoid big repairs later and keep your gear working well with proper treatment.

How to Check for Coating Problems and Corrosion

Having a regular inspection plan is important for catching problems early. A mix of routine in-house checks and periodic professional technical service can help find and fix small issues before they turn serious.

How Staff Can Inspect for Problems

- Look for rust, discoloration, and damaged coating on equipment and wall surfaces

- Check for bubbling, cracking, flaking, or loss of shine

- Pay attention to changes in the surface or texture that might indicate system failure

Train staff on what to watch for. Self-inspections can find trouble early even if they don’t replace professional reviews that assess overall project performance.

Benefits of Professional Inspections

- Find hidden or severe corrosion and coating failure

- Maintain licensing and keep warranties valid

- Get an expert opinion on which repairs or coatings are best

- Plan and track future maintenance to avoid surprises

Contractors with the right credentials and experience will make sure coatings are applied properly and meet safety requirements.

How To Prepare Surfaces for New Coatings

Surface preparation is one of the most important steps before putting on a new coating. If the surface isn’t cleaned and prepared well, the coating won’t stick or protect like it should.

Painting over rust or dirt won’t solve anything — corrosion will keep spreading underneath, compromising the entire system.

Cleaning and Removing Contaminants

- Strip off all old coatings and rust.

- Use cleaning methods like pressure washing or steam cleaning for dirt, grease, or oil.

- Abrasive blasting may be needed to get down to bare metal.

- Rinse and dry everything fully before applying the new coating.

Creating the Right Surface Texture

- Roughen up the surface to match the new coating’s needs (often 2-3 mils as the manufacturer suggests). This helps the coating stick better and last longer.

- Inspect after preparing to check cleanliness and texture.

Proper preparation is the main step for long-lasting results.

Steps To Renewing Protective Coatings

Once surfaces are ready, it’s time to apply the new coating. Doing this right is just as important as preparation.

Best Practices for Applying Coatings

- Make sure the coating fully covers the whole surface.

- Apply with care using spray, brush, or another method as recommended.

- Follow the manufacturer’s instructions for layers, timing, and curing.

- Keep the work area clean to avoid dust or debris in the coating.

- Check each step to avoid thin spots or mistakes.

A final inspection before and after application helps make sure everything is done right and keeps warranties valid.

Quality Control and Curing

- Monitor air temperature and humidity-these affect drying and curing performance.

- Mix the coating materials correctly using proper technology and equipment.

- Allow enough drying and curing time according to the product instructions.

- Perform another technical inspection when curing is complete.

- If everything goes right, your equipment gets a solid, long-lasting protective layer.

How To Maintain Renewed Coatings for Best Results

Applying a coating is an investment. Keeping it in good shape over time is key to getting the most value and longest lifespan from your protective coating system.

Regular Maintenance and Inspections

- Inspect surfaces regularly for cracks, chips, blisters, or wear that might require coating repair.

- Act quickly if you spot small problems — fixing them early keeps the coating working and maintains performance.

- For high-use areas, apply extra maintenance coats as needed through professional service.

- Monitor wall and surface conditions in construction environments.

Cleaning and Storage Tips

- Clean coatings often to remove dirt, oil, and chemicals that could reduce lifespan.

- Follow the coating manufacturer’s technical suggestions for cleaning methods (pressure washing, gentle detergents, etc.).

- Dry parts well and store them out of the weather to maintain system integrity.

- Use covers or padding to prevent scratches and damage in storage.

- Proper care slows down wear and keeps coatings working as a protective solution.

Why Renewing Coatings Saves Money Over Time

Renewing industrial coatings may seem like a big upfront cost, but it’s actually a smart solution to save money long-term by preventing much bigger problems down the line.

Cutting Downtime and Repair Costs

- Less unplanned downtime and fewer emergency repairs

- More up-time means more productivity and income

- Early fixes save on costly restoration or complete replacement

Safer, Longer-Lasting Equipment

- Reduces safety risks and helps stay in line with regulations

- Equipment lasts longer, reducing the need to buy new parts

- Keeps workers safe and prevents fines or environmental spills

In short, renewing coatings protects your investment and keeps everything running smoother for years.

Start Protecting Your Facility — Work With Corrosion Control Experts

Stopping industrial corrosion is a demanding task that requires the right technical know-how and a forward-thinking mindset.

If you want to protect your assets, keep your operations running, and get the most life out of your equipment, don’t wait. Investing in proven corrosion control solutions, like updating protective coatings and addressing concrete repair needs, brings real savings and safety benefits.

Contact Nova Construction Services today! We’ll handle everything from surface preparation to applying new coatings the right way. We deliver clear estimates, careful prep, daily checks during work, and a detailed walkthrough at project completion.

Got a project in mind? Let's chat about bringing your construction vision to life!